At its core, for assembly line manufacturing, Six Sigma could be made to work. It was bounded by the realities of physical science and not subject to whims of management. Very quickly management tweaked Six Sigma to include its whims. I have always said

Show me an employment ad for a company demanding Six Sigma training and I will show you a company that is going out of business.

I watched it happen at many of my clients. Navistar kept selling off business units and pushing Six Sigma as its possible salvation right to the edge of bankruptcy. Navistar is now owned by Volkswagen. Let us not forget the mantra of fool’s management:

If your only tools is a hammer, every problem must be a nail.

This, in a shot glass, is what happened with Six Sigma. One of the biggest CEO factories pushing this and other false management philosophies was recently shuttered, GE’s Crotonville. After over a year on the market GE refused to suffer the humiliation Keller Business School had to endure. They had to basically pay a California company to take the scam . . . err . . . I mean school, off their hands.

You knew it was a scam when

The “Define” step included management’s desires. Management tried to apply Six Sigma to everything, not just physical manufacturing processes. Where this failed spectacularly was when it got combined with Lean.

If you heard management utter a phrase like that, then you have shit management. I couldn’t find the infamous Dilbert cartoon for

Any job done by two people can be done by one at half the cost.

Pointy Haired Boss

This lead to the completely inept business mantra

A depth of one is more than sufficient for any task.

Inept Business Mantra

If you keep halving your staff, eventually you are down to one person that knows anything about multiple critical business systems.

Oh, but you’ve got documentation right?

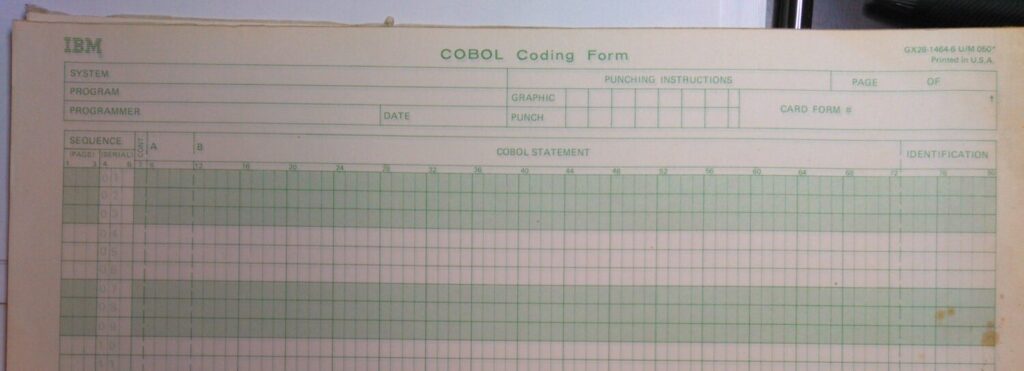

You can find a bit more in-depth information on this in The Minimum You Need to Know About the Phallus of Agile. When I started in IT, we had to write our code on coding sheets.

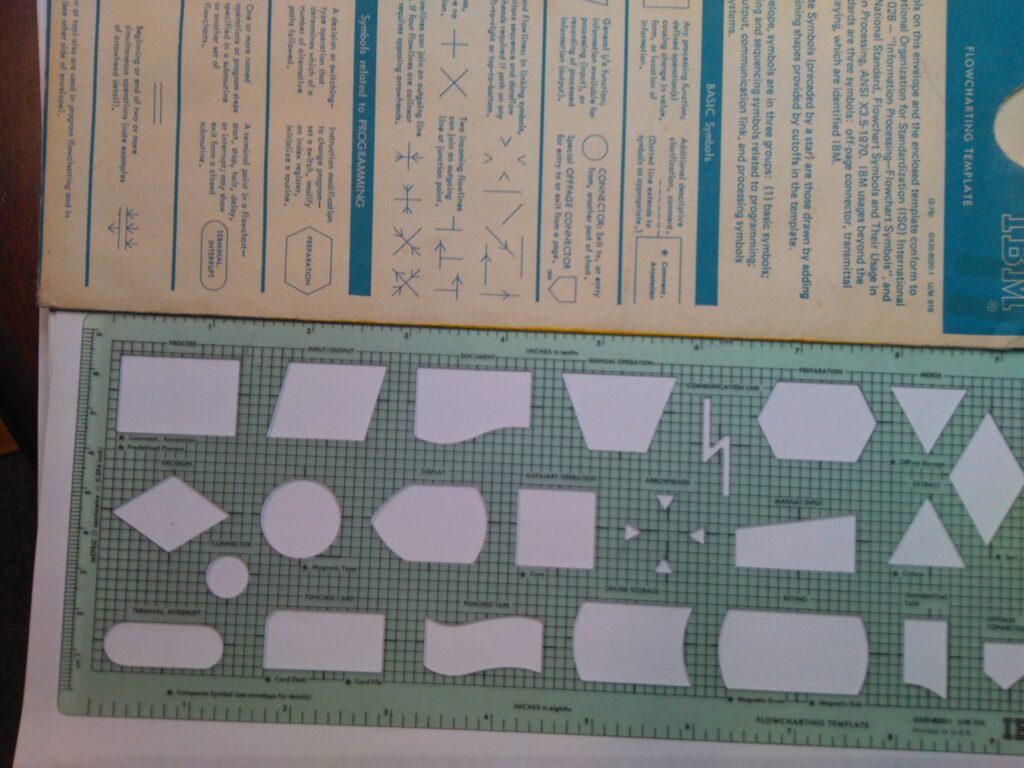

That was after we had drawn a flowchart using one of these.

For a system it could look something like this

Each responsibility swim lane labeled by application area or department. Each of the boxes would themselves have full flowcharts and documentation.

Then you got access to one of these to type your code in.

Shops always kept the flowcharts. Some kept the original coding sheets. Because magnetic storage was expensive and media failures common, most shops printed out the final version of the program, put it in a binder, and stored it in a special cabinet or room.

When everything failed this was your backup. Get good at typing!

These systems written in the 1960s through early 1980s were custom core business systems. They just ran and helped the company make money. It usually took a large staff of 30-50 people to create one. At least one of them had to actually “know the business” to come up with the design. In The Minimum You Need to Know About the Phallus of Agile I tell you the story of how Sears ruled the catalog world by introducing computers. Every mail order form of the day had “Please allow 6-8 weeks for delivery” at the bottom of it. Sears was pretty much the first one to have “Please allow 4-6 weeks for delivery.” Despite people paying with money orders and paper checks, custom software allowed them to streamline the process. A large staff with tons of documentation was necessary for survival.

Enter Six Sigma and LEAN

“Any job that can be done by two people can be done by one at half the cost.” Hey! Let’s “right-size” our staff. Actually those older people cost too much money. Let’s get rid of everyone over 40 and replace half of them with twenty-somethings . . . and somehow avoid prison.

Institutional knowledge gushed out the front door.

“We are paying too much for rent!” We have PCs, file servers, and scanners. Let’s scan all of this paper documentation onto the file server where everyone can get to it then dispose of the stuff. That will save us over 1000 square feet of office space.

“Programmers spend too much time replicating feature/fix documentation in the comments. Let’s just have them use the ticket number to save time and space!” To be a real mover and shaker in MBA world you cannot stay anyplace two years. Every new MBA had a different ticket system they liked. Eight years in their were ticket numbers for systems that hadn’t existed in six years.

“Backing up our SAN (Storage Area Network) costs too much!” Let’s put in a policy to delete all files that haven’t been touched in 10 years. That will halve our storage footprint and save us close to a million dollars in both labor and off-site backup storage.

Can You See What Happened?

At first they still had some older employees with deep institutional knowledge so the age discrimination they got away with didn’t completely kill the company. As network storage increased along with security, only the people who actually scanned the original systems documentation knew where anything was . . . then they also got right-sized.

These systems were written in the 1960s-1970s. They just worked. Nobody really knew how they worked, but they just worked. Unless a disk ran out of space or there was some other hardware failure, nobody touched them. More importantly, nobody had any reason to keep track of the documentation for them because they never needed maintenance.

Even nuking all of the documentation isn’t what buried these companies . . . per-se. It was trying to migrate. As the companies went under and got bought, the larger, better run company, wanted to migrate to their favorite canned packages for everything.

- What format is your data?

- How is it organized?

- Where are you business contracts?

- How about your systems documentation?

The only “documentation” left was the source code and there is no “why” in the comments.

It Wasn’t Just Custom Software

Every aspect of business got pooched by Six Sigma and LEAN. Contracts with franchise/retail locations got scanned then lost. When the new owners tried to migrate to a new system they found out these entities actually kept their paper versions.

Rumor has it at least one life insurance company had somehow gotten Whole Life policy text for policies issued from the 1940s forward onto their mainframe. “Not been touched for ten years” caused them to be nuked. They had been nuked long enough no backups existed. Then COVID hit and grieving loved ones tried to file claims.

One client had a SAS license for both their OpenVMS systems and their IBM mainframe. There were only two users on the OpenVMS system. During a “cut costs” frenzy someone who had no idea why that license existed for those two users got rid of it to save $15K/yr. They had mainframe accounts created for those two users and trumpeted how they saved the company $15K/yr.

Why was important. There were two small files needed from the IBM mainframe and all the rest of the data needed for those two users was on the OpenVMS systems. A nightly job had to be created to copy huge amounts of data over to the blue box. There wasn’t enough disk space. Not only that, the statistical calculations took up an incredible amount of processing power.

In a “cost cutting” move to save $15K/month one department forced another department to perform a $2 million system upgrade 3 years early.

Tunnel Vision

It is said that Henry Ford made his son start off in the mail room to “learn the business.” It is certainly true that this was the path for many CEOs. Goldman Sachs had a CEO that started out as a janitor. They learned the business. Not just a single department for under two years, they learned the entire business. They knew what had to work to make it work.

People wanted a fast path to CEO so MBA schools and CEO factories teaching Six Sigma popped up like weeds. MBAs were taught to have tunnel vision about their department only. They weren’t at a company to solve all its problems, just to be a mover and a shaker. “Cut Costs” in your department, grab a big bonus, then move on. Business be damned!

Summary

Quietly, the financial world is admitting that MBA schools and CEO factories were a tragic mistake. Some of the biggest names have either been shuttered or had the owners pay someone to take them. Working up from mail room to boardroom is the proper way for big named companies that survive.

Six Sigma was always a joke. When you could scope it to be disconnected from all reality it was just a prescription for disaster.

You need a 30 year vision for your company, not a 30 day vision.