I don’t think there could be more disinformation about anything in home hobbyist x86 computer world than there is about the red washer. Almost as much disinformation as the metal washer and different length metal stand-offs. Yes, motherboard and case designs have gotten better since the 1980s, but that is not an excuse to throw the red washers away. Keep in mind, I’ve been building computers since the AST Premium 286 came out.

I went through a long period after that where I always built my own. I’m actually going to build another one soon. For years I had been buying HP and Lenovo small form factor desktops, but I priced a new Engineering desktop from HP and they wanted $8K. I can build something close for around $2K.

The 1980s

Every postal worker in America hated Computer Shopper magazine.

I think it used to have something like four columns and two articles. Everything else was advertising, mostly color. The magazine itself had a massive page size, far greater than 8.5×11 and it was almost Sears catalog thick. You could walk into a Computerland and spend north of $5K on a computer or you could cobble one together for about $800 if you scoured every ad in Computer Shopper.

PC Magazine has a great pictorial on this era. ComputerLand targeted corporations and small businesses. Big brand name computers like IBM and DEC didn’t allow little shops to sell their stuff.

Necessity of Poverty

Most fresh-out-of-college computer programmers were earning $20,000 – $25,000 per year at this time. We had student loans to pay for and cars that were “good enough for college” to replace. $5K for a computer was a huge chunk of our income. Not everyone had credit cards then and those of us who did had credit limits well south of that magic $5K. Computer Shopper was the only way we could have a home computer. Keep in mind, we were all working on Mid-range and Mainframe computers for our day jobs. This PC stuff was a get-rich-quick scheme like crypto currency is today.

Build it yourself became the path to riches and glory. It also came with one big problem.

How programmers does it take to change a light bulb? None, it’s a hardware problem.

Programmer’s mantra

Shop Class Bites You

Every high school forced kids to take at least one shop class. Hey, learning how to sharpen a screw driver, build a cabinet, and perform minor engine repairs is something everyone should learn in high school. Most everyone changed their own oil because it was half the price of going to an oil change place.

One thing you were taught when it came to engine (even lawn mower) repairs was make sure it is tight. Not good advice when installing a motherboard into a case. More than one friend/coworker/classmate really tightened a screw only to crack their motherboard. For most of them the computer would work until it got warm then it would crash or have other weird errors.

The Downside of Cheap

Much of the stuff in Computer Shopper was cheap for a reason. China was making what today we know as “North Korean knock-off quality” products and dumping them on the American market. A tower case through a reputable place like JDR Microdevices would cost $120. You could get a mid-tower Chinese special for $35 if you turned enough pages. I bought one of those. There wasn’t a buffed edge in the case. I gashed myself multiple times installing the motherboard and other components.

In China they just stamped the cases out, no sanding, no buffing, bleed to death you American scum! JDR sold products from better manufacturers. Once I saved up enough I pieced together a shiny new computer with that $120 tower from JDR. I sold that 386 to some dude in the navy for something like $100. He cut his hand on the thing carrying it out of my place.

Downside of Cheap Part 2 – No Case Quality Control

Besides having no buffed edges, the cases weren’t a uniform depth. There started to be an almost uniform bag of fasteners that came with everything. The better bags had different height metal stand-offs so you could raise the motherboard high enough to get an add-in card to seat. I kid you not. Friends fried more than one board because cards were half seated.

I wish I had saved some of the viciously bent brackets I had on cards. There was no screw holding that card in. I had to bend the top hook almost straight up to get the card fully seated. This was the norm for do-it-yourself builds in this era.

Oh, the lesser bags of fasteners came with only one size/height metal standoff. Along with the red washers came a pile of metal washers. That’s right, they wanted you to somehow stack metal washers on the pair of metal stand-offs and somehow slide your mobo into place without knocking them off.

Downside of Cheap Part 3 – No Mobo Quality Control

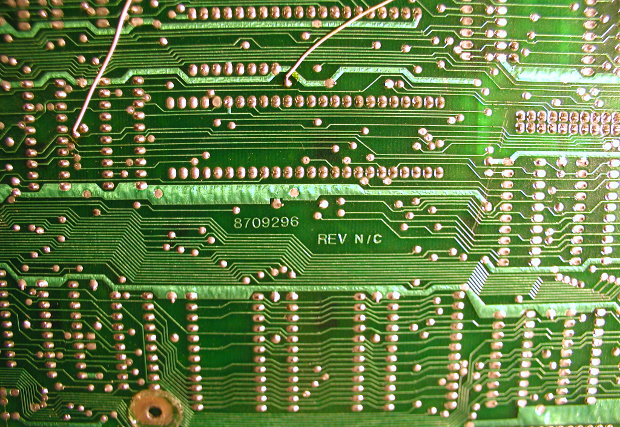

Today you are used to motherboards that look like this on the back side.

All of the little solder points uniformly buffed and smooth to the touch. The mail order boards we were buying then sometimes had half a pin sticking out the back. They would prick your fingers like a diabetes test. In order to save money some manufacturers found out ways to reduce the number of layers in the board. Fine. But they used the same sockets because they were cheaper.

When you buy sockets or chips with pins long enough for an 8-layer board but you mount them on a 4-layer board there is a lot more pin sticking out. You’re supposed to nip those off, not just ship the thing to a programmer. Many a programmer installed said board with the supplied stand-offs only to fry the board on first power-up. Some, if not all of the pins were long enough to touch the metal case and ground the thing out.

Magic Smoke. Easy to get out of a motherboard, impossible to put back.

Shop Class Bites You – Part 2

If you want a screw or nail to “hold more” use one with a bigger head.

Shop class

Yeah, works for construction, bad advice in the computer world. We used to have case screws, drive screws, card screws, and mobo screws. They were all different threads and sizes. Then some green visor’ed fool decided “Ack! We should make them the same.” Well, it turned out you needed bigger heads for the case, but at least now they were the same diameter and thread as all the other screws, so that makes them interchangeable, right?

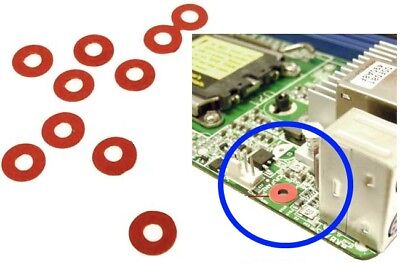

There were always traces and/or components that would either make contact with or get crushed by the larger screw head. A paper red washer was near worthless at protection from over tightening. The felt-like red washer was what you wanted. It was a little thicker and provided more cushion.

The only real thing the paper washer did for you was point out the fact the screw you were about to use had a much bigger head than the red washer. Theoretically the paper stopped some grounding but paper tends to absorb humidity thus becoming conductive.

Summary

Do you need the red washer? Yes. You need the felt-like ones.

It goes on the top of the mobo where you are going to use a screw into the metal stand-off.

What purpose does it serve? Stops screw head from grounding something it shouldn’t. Helps protect against over tightening. Keeps the screw head slightly elevated so when human/pet hair, dust, etc. get to that part of the mobo it doesn’t ground something further away out.

“But I bought an insert-brand-name-here desktop and they didn’t use them.” Correct. Those units tend to be assembled by robot in a controlled factory setting. The green visor people who used to buy “whatever screw is cheapest this week” have all been fired. A screw with a metal head smaller than that metal ring is always inserted. By the time human hair/dust/debris cause a problem the unit will be out of warranty.

“I’ve never used them.” You’ve gotten lucky. Today’s mother boards are more idiot proof than those of yesteryear and cases have more quality control. You are still one distracted conversation away from using a screw with an over-sized head causing a problem. The red washer is your last reminder.

Always buy the felt-like ones. They are a little thicker and work a little better.